He compactor unit works as the sliding wheel on its rack, powered by the hydraulic pressure, moves up and down along the track of the rolling element. The hydraulic cylinders enable a stable and even compressing process, and is easy to control and adjust the clamping force smoothly. Both the top and bottom compressing plates are comprised of sets of adjustable compressing delivery rolls. Plate blank, either normally-set or upside-down, can go in and out easily at any position.

The hydraulic station and the electrical controller are two separate parts. The oil pressure and flux of the hydraulics can be adjusted, so as to realize the ideal clamping force and speed. The hydraulic valves are integrated before they are connected, so the structure is more compact and easy to maintain. Electrical apparatuses are designed into a cabinet, with all control buttons as well as indicators on the panel, which is well-organized and easy to operate on.

The power system is at the bottom of the rack. The power generated by the brake dynamo is passed on to the worm and worm-wheel, lowered down by the decelerator, and then is further passed on to the chain-wheel, the chain and finally to the turnover.

| Specification | ||

|---|---|---|

| Cylinder stroke | 490mm | 500mm |

| Max.opening limit | 1367mm | 900mm |

| Turnover angle | 0-180° | 0-180° |

| Length of turnover plate | 2600mm | 2600mm |

| Power | 3+1.5kw | 3+2.2kw |

| Overall dimension | 2400×2370×2280 mm | 2760x3375x2835mm |

| Approx weight | 1.5T | 4.5T |

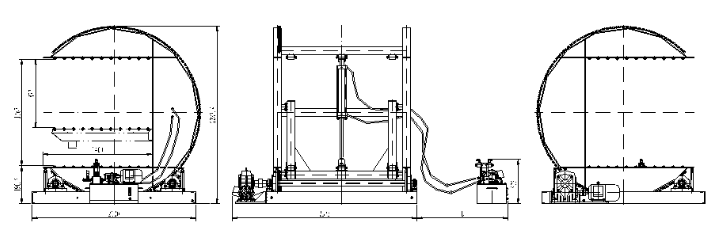

Drawing